Modular and compact design

Up to 70% faster feasibility & 15% faster delivery

SmartStation, ConveyInsights™, Metso components

In-pit crush and convey solutions - Redefining IPCC productivity

We understand no two IPCC projects are alike, so we treat them that way from beginning to execution. Metso's IPCC Planning Services team supports mining and EPC companies by applying our software solutions, William Conveyor Explorer and Metso’s Crush and Convey Resource Center. Using these solutions you can decrease feasibility study time by up to 70% as 3D models and specifications are instantly available.

Our services break down into 3 stages:

- Assess: Trade-off study to identify value

- Analyze: Integrated mine planning and equipment design to maximize value

- Advance: Detailed execution program ready for delivery

With the 3 stage approach, we deliver a quick and efficient project definition.

When working with our team we develop your optimal solution based on your operational goals while using proven technology.

- Crushing: Foresight™ semi-mobile primary gyratory (SMPG), Lokotrack® mobile solutions, FIT™ stations

- Conveying: Foresight™ overland conveyors, mobile

- Stacking: Coarse ore stackers (Spreaders and mobile stacking bridges also available - Read more about co-operation agreement)

Metso services support is unmatched by delivering either pre-designed or customizable packages to deliver performance outcomes. Our aim is not only deliver a successful IPCC operation, but then also keep it running at an optimal level. Our featured services are:

- Life Cycle Services (LCS)

- Off site pre-assembly

- On site assembly

- Process optimization

- Connected analytics

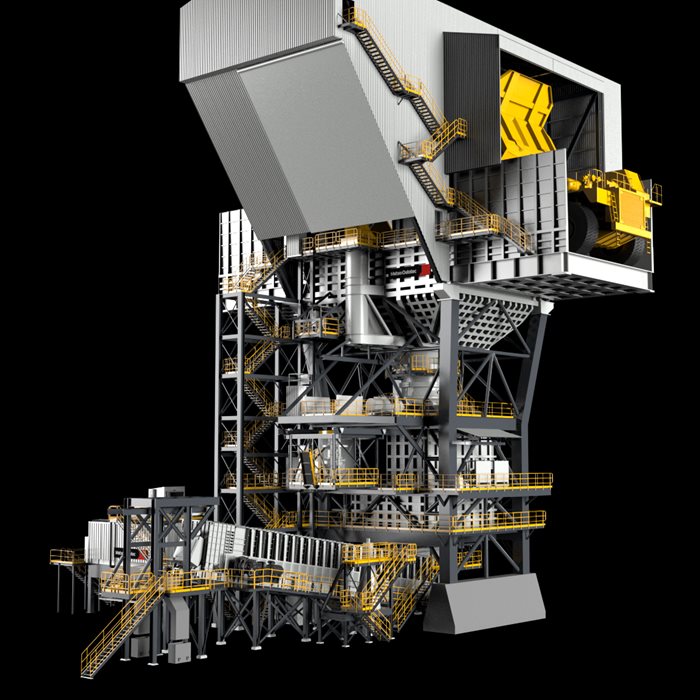

The Metso Foresight™ SMPG station are high capacity and modular solutions that are a key highlight in our IPCC designs.

- SmartStation features for optimal processing, reducing wear and plant height whilst autonomously controlling material size

- Improving maintainability through improved crusher access and plant area isolation

- Reduce height and downtime with SMPG feeder

- Variable capacities with different crushers and truck sizes

The Foresight™ SMPG station includes our Superior™ MKIII primary gyratory crusher. This brings additional benefits such as reduced downtime by up to 70%, and increased capacities by up to 30%.

Learn more about the Foresight™ SMPG station.

Metso Foresight™ overland conveyors can be customized with existing Foresight modules and use of Metso’s standard premium conveyor components. Bolted assembly and pre-commissioning can be done offsite and transported onsite. Utilize the Metso Crush and Convey Resource Center to increase the speed of feasibility. Access online sizing and selection and assess conveyor route options.

Speed - 70% faster feasibility and 15% faster delivery

Productization for today’s mining - ease of planning, configuration, assessment and quoting

Configured for high-capacity - up to 15,000 tons/hour capacity

Learn more about the Foresight Conveyors